Best TDR for PCB Manufacturing

In modern electronics, precision and signal reliability play

a critical role in ensuring high-performance devices. One of the most essential

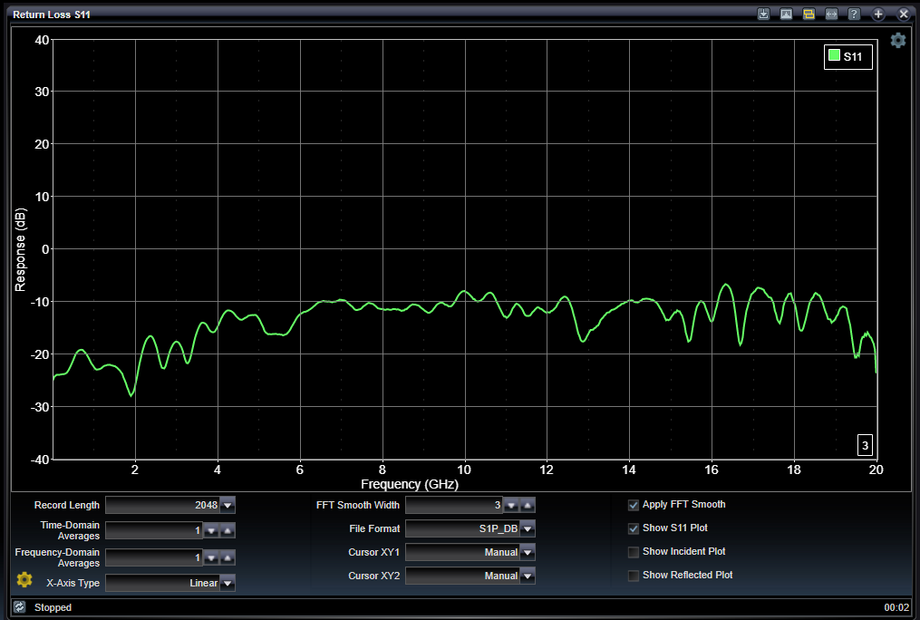

testing methods used during production is Time Domain Reflectometry (TDR).

Choosing the Best TDR for PCB manufacturing

helps manufacturers detect impedance mismatches, signal reflections, and

transmission issues before products reach the market. BitWise Laboratories

specializes in advanced testing solutions that help PCB manufacturers achieve

superior quality and consistency.

Printed Circuit Boards (PCBs) are the backbone of electronic

devices, from consumer gadgets to aerospace systems. As circuit speeds

increase, maintaining controlled impedance becomes more challenging. Even minor

variations in trace width, dielectric thickness, or material quality can lead

to signal loss or distortion. This is where TDR testing becomes invaluable. By

sending fast electrical pulses through PCB traces and analyzing reflections,

engineers can accurately measure impedance and identify defects.

Using the Best TDR for PCB manufacturing allows engineers to

verify design accuracy during both prototype and mass production stages. It

ensures that transmission lines meet required specifications and comply with

industry standards. Early detection of faults reduces costly redesigns,

improves product reliability, and shortens development cycles. Manufacturers

can also optimize layer stackups and material selection based on accurate

measurement data.

At BitWise Laboratories,

advanced TDR testing solutions are designed to deliver precise and repeatable

measurements. Their expertise supports industries such as telecommunications,

automotive electronics, medical devices, and high-speed computing. With modern

PCB designs operating at higher frequencies, signal integrity testing has

become more important than ever. Accurate impedance profiling helps prevent

data errors, electromagnetic interference, and performance instability.

Another advantage of professional TDR testing is quality

assurance. Manufacturers can maintain strict production consistency by

validating each batch of PCBs against defined impedance targets. This improves

customer confidence and reduces field failures. Additionally, TDR analysis

helps engineers troubleshoot complex multilayer boards where visual inspection

alone cannot detect internal issues.

As electronic devices continue to evolve toward faster

speeds and compact designs, reliable testing methods are no longer

optional—they are essential. Investing in advanced testing solutions ensures

that products meet performance expectations while minimizing manufacturing

risks. Companies looking to enhance PCB performance and durability should

prioritize professional testing services backed by technical expertise.

In conclusion, selecting the right testing partner and

technology is key to achieving flawless PCB performance. With industry

knowledge and precision measurement capabilities, BitWise Laboratories helps

manufacturers maintain signal integrity and deliver high-quality electronic

products through accurate TDR analysis.

For more visit us: https://bitwiselabs.com/

.png)

Comments

Post a Comment